MV Mobility offers light weight crash worthy composite structures in glass fibre and carbon fibre systems using our inhouse developed polymers / chemistry best suited to meet the requirements of strength, light weight and fire regulations including EN 45545 / HL3, UIC and various other international standards.

We have deployed varied techniques to suit the specific requirements of transportation sector including:

Hand layup

Resin transfer moulding

Vacuum moulding

Dedicated simulation softwares are deployed to visualise the interiors / colour combination /concepts to our customers. We ensure fast pro-typing to enable our customers finalized their designs and thereby facilitate mass production of these structures.

Having reach experience in different grades and metallurgies of alluminium, being used in transporation sector, MV Mobility can offer Light Weight Alluminium Structures to suit the applications.

Different techniques engineering press forming, CNC bending, vacuum forming, die moulding, manual / robotic welding etc. are deployed to offered alluminium structural solutions specific to the requirement of transporation sector.

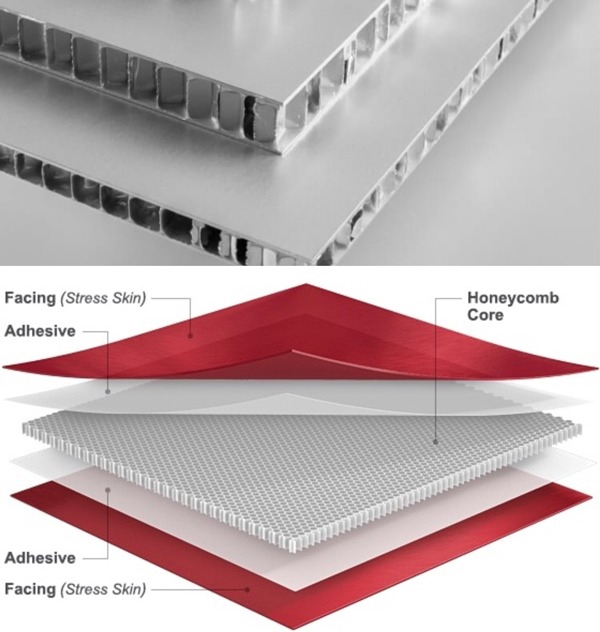

MV Mobility manufactures high quality Aluminium Honeycomb core panels that are used in a wide variety of applications. Aluminium honeycomb is a preferred material because of its high strength-to-weight ratio and used in applications wherever low weight and crashworthiness are key factors. Our Honeycomb panels are being supplied for Rail Transportation for use as partition panels inside passenger coaches. Top Surface decorative panels can be supplied in numerous designs, colours & patterns to suit the theme of coach interiors

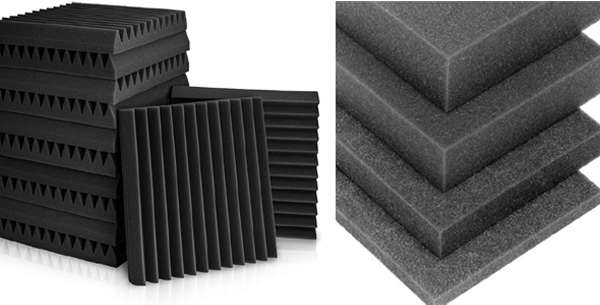

Insulation of Side Walls, Underframe & A/C Ducts

Low Density 15kg/m3 Closed Cell Polyolefin Thermal Insulation

Low Density 12 Kg/m3 Open Cell Melamine Foam

Low Density 12 Kg/m3 Open Cell Melamine Foam