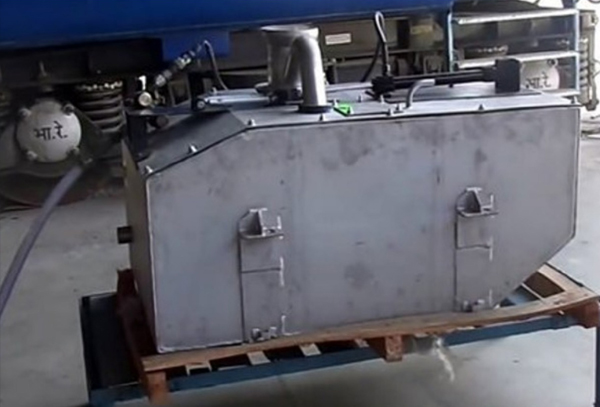

MV Mobility possesses a state-of-the-art Assembly/Integration & Testing facility for Bio Vacuum Toilet Evacuation Systems especially designed & developed for High speed Trains & Transportation. The Systems can be supplied independently or integrated with our Light-Weight Composite Toilet Modules.

Working Principle: Vacuum intermediate type Evacuation system comprises of an intermediate tank between toilet module and bio digester tank. In a standby mode, there is no vacuum in the bio digester tank and intermediate tank. During flush actuation, Vacuum generator will temporarily generate vacuum in intermediate tank, then the inlet pinch valve between toilet module and intermediate tank opens. The sewage in the toilet module will be sucked into intermediate tank by vacuum, and then the inlet pinch valve will close. The compressed air is then introduced into intermediate tank, the outlet pinch valve between intermediate tank and bio digester tank will open after the setting time, and then the sewage in the intermediate tank will be transferred to bio digester tank. This completes the flushing cycle.

A Bio-Digester system is a complete waste management solution which reduces solid human waste to Bio-gas and water, with the help of a bacterial Inoculum. Biological decomposition of Human waste is done in bio-digester tanks with the help of anaerobic bacteria. Bio-Toilet is an innovative technology for disposal of solid human waste in an eco-friendly, economical and hygienic manner. The residual water from Bio-Toilet is Colorless, odorless and devoid of any solid particles. It Requires no further treatment / waste management & can be used for irrigation purposes.